I’ve built a bunch of electric ukulele, but all of them have been modeled after full size electric guitars. For this project I set out to design my own electric ukulele. I think it turned out great.

My other electric ukuleles have been modeled after guitars from Fender and Gibson. Can you name all of these models??

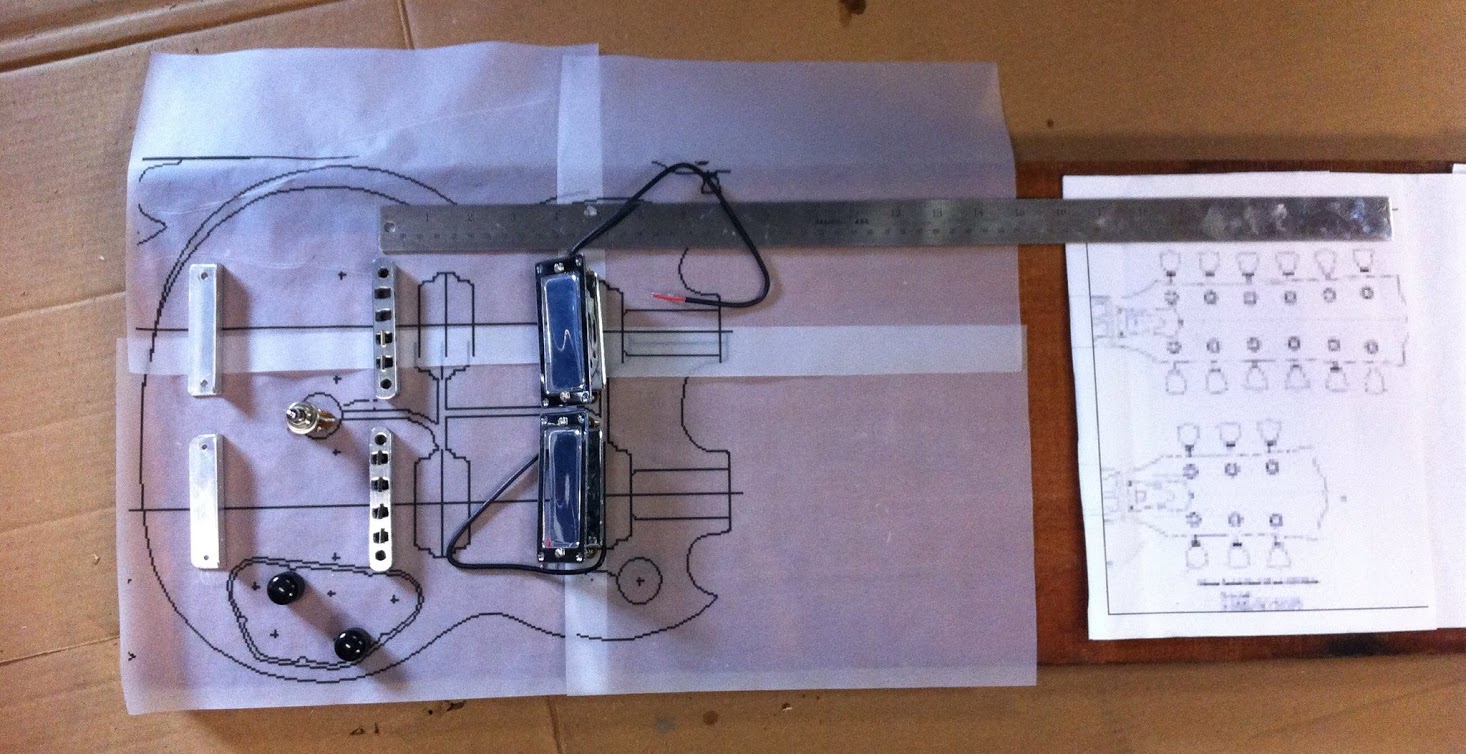

Here are some sketches that I drew as I designed this instrument. You can see how how the designed changed and progressed.

I probably shouldn’t admit this, but part of the headstock design was influenced by the fact that I had quite a few left hand tuners in my possession. I purchased sets of 3-on-a-side tuners to use for my Fender style builds, but only needed the right hand ones.

After all of the parts were fitted, I leveled the body with some putty. It is important to have the body as smooth as possible before the prime, and color coats.

The body was primed, given a nitrocellulose color coat and then a nitrocellulose clear coat.

I wanted to try having the volume knob on the side of the body instead of the top. Doing this also allowed for a bigger cavity to house a push/pull switch to split the hot rail humbucker. To keep the back and top as minimalist as possible, I drilled long holes from the pickup cavity to the combination strap peg/jack.

I’ve named this the “Wave Ukulele” because the body made me think about waves crashing against the shore. Once I gave this a name, I tied other design element to this theme. The body is Sea Foam Green, and the fret markers, side markers and even the cap on the volume knob are abalone.

This build was my first foray into the world of fanned frets. The bottom string has a scale length of 17 inches and the top is 18 inches. It’s a little different to play, but it’s very easy to get used to. Make your own fanned fretboard with this tutorial.

See it in action!

[youtube=http://www.youtube.com/watch?v=ak2wapy1hdc&w=480&h=360]