The term U-Bass is a relatively new one, owned by Kala. It is there trade name for their 4-string full range bass ukelele. It has a half-scale neck that measures 21″ that uses special polyurethane strings reproduce the sounds of a full size upright bass. The ‘u’ part of the name stems from the fact that it is built around either a solid or an acoustic baritone ukelele body. It can be bought either as a 16 frets (with the neck meeting the body at the 12th fret), fretted or fretless model.

On Sunday evening I was lucky enough to meet Paris from The Pukes and she let me have a look at her solid body u-bass. We suspect that it might be the only solid body u-bass in the U.K. at the moment, but if you know of any others, we would love to hear from you. Please leave a comment below.

Paris reckons it plays really well and the short chance I got to play, it felt nice in my hands. The strings didn’t feel at all sticky, (see the Ashbory below for more on that) but I didn’t get a chance to plug it in.

Paris was also kind enough to flip the u-bass over and let us take a little look inside the preamp cavity. You can see in here a small CR-2032 battery, the same kind that is inside the pre-amp of my Kala Tenor uke. In the years I have owned that uke, I have only ever had to change the battery once or twice and they are available all over the place now. Our local 99p shop sells 5 for a pound 😉

So Paris has the only solid body we know of, but we did see this acoustic version down at John T’s Shopand we were very impressed with that. It is smaller than a guitar, but has a warm acoustic sound like a upright bass.

I had played a Ashbory DeArmnd short scale bass a few years ago. Like the u-bass, this half scale unit was a light weight, poly-stringed bass and I guess in many ways it inspired the newer u-bass. When I played this, the strings were a little sticky, but it was perfectly playable. The company Ashbory is now owned by Fender.

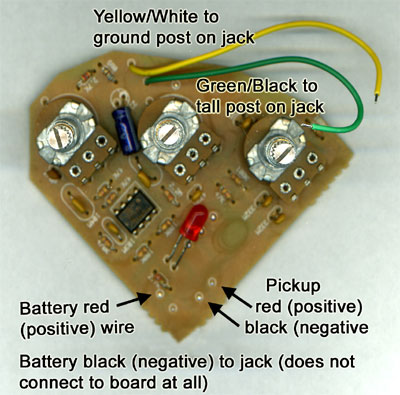

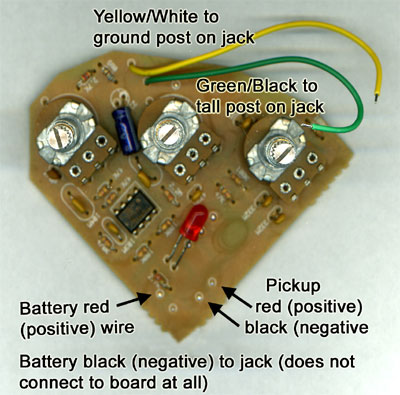

It also has a little pre-ap built into it’s cavity which you can find pictures of below.

You can download the schematic for the Ashbory’s preamp from largesound. I think this could be a very useful schematic for any nylon string uke pre-amp you might be building.